Stainless steel tube

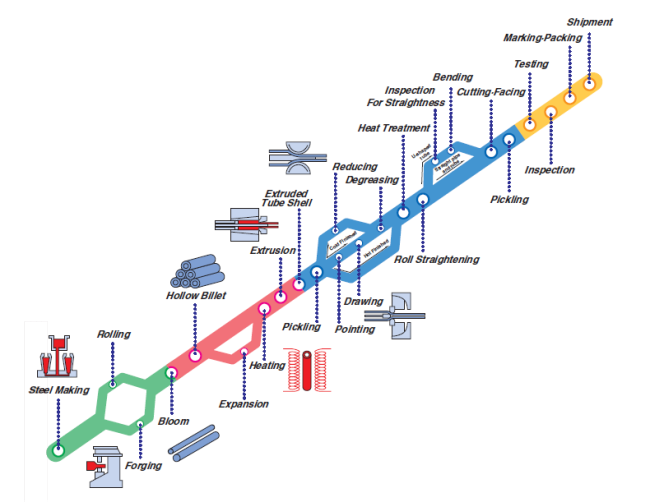

Production Process of Seamless Stainless Steel Tubes and Pipe

Maruichi Stainless Tube's seamless stainless tubes and pipe are made with

a variety of sophisticated equipment. Our high-quality ingots are produced

utilizing electric arc melting and vacuum-oxygen decarburization (VOD).

Our vacuum induction melting process (VIM), electroslag remelting process

(ESR), and vacuum arc remelting process (VAR) are applicable for special

use. These ingots are rolled or forged into blooms that are then further

processed using the Ugine Sejournet hot extrusion process and turned into

high-quality seamless stainless tubes and pipe. Smalldiameter and precision

tubes and pipe are manufactured by a drawing and reducing process.